Call Us: +91 33 4604 6698 / 99

Search

Call Us: +91 33 4604 6698 / 99

Search

Air Intake Systems (Turbo Machinery)

Air intake filters and systems are crucial for turbomachinery, especially gas turbines, as they protect the engine from damaging particles and contaminants that can cause erosion, fouling, or corrosion. A well-designed system ensures efficient operation, extended lifespan, and reduced maintenance costs.

Auto Roll Filter

AFI's Auto Roll Filter is the most versatile product on the market today, its the most advance unit to meet the demands of variable air volume systems. The roll filter concept combined with fiberglass media provides application versatility & air cleaning economy. Our unit comes along with power packed gear motor drive, control box containing timer, runout light & hand-off-auto selectors switch completely factory wired.

Auto Viscous Filters

AFi's Auto Viscous filter is a self cleaning viscous filter using a rotating curtain of metal panels as the filtering mat. Behind the filter mat is an endless roll of oil drop eliminator. A timer controlled, totally enclosed thermally protected geared motor rotates the filter media & oil drop eliminator which pass through a viscous oil bath located at the bottom of the filter. The viscous oil cleans the filter media & the oil eliminator minimizes the carry over oil droplets into the air stream. The sludge collected in the oil bath needs to be cleaned periodically.

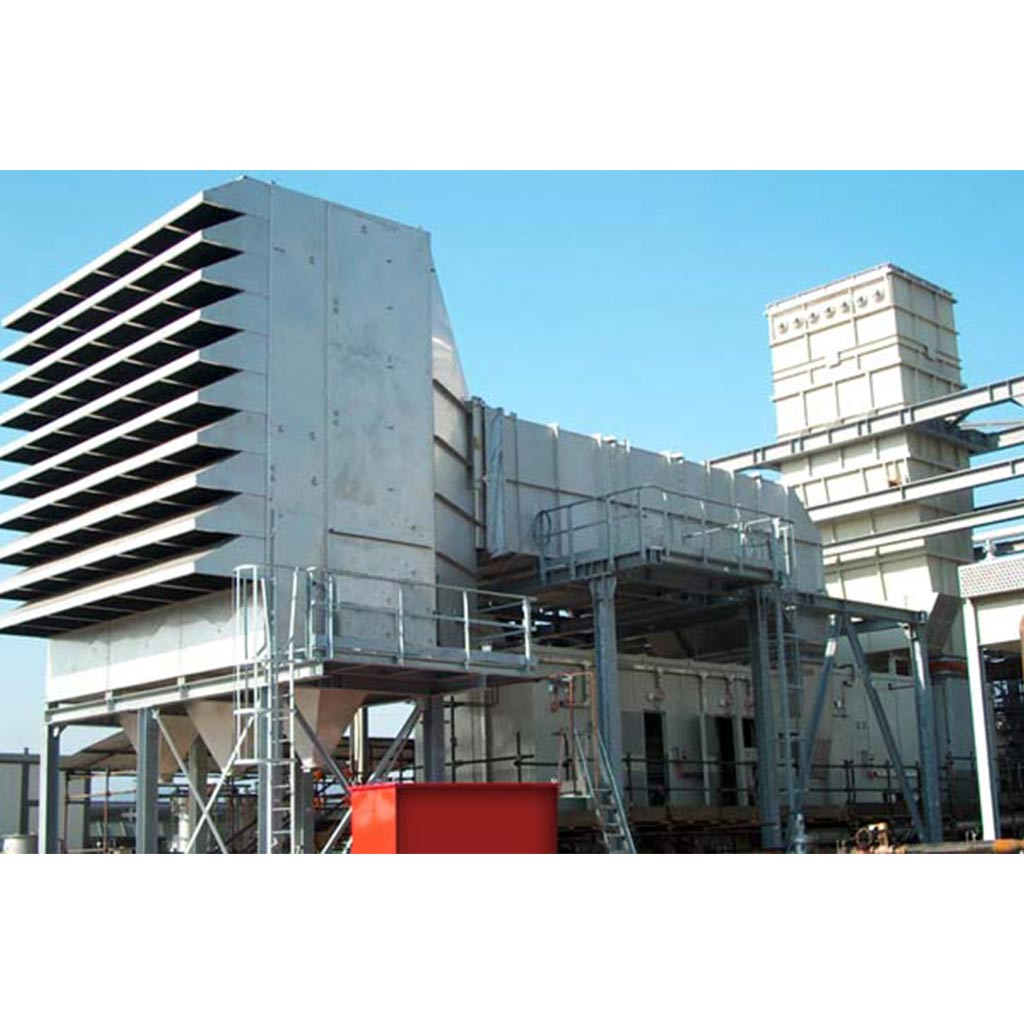

Combined Filter System

AFi's unique Combined systems, pulse system with final static (H)EPA filtration stage, are designed to protect rotating machinery operating in corrosive and high dust load environments. In these conditions, conventional systems would typically suffer from frequent service intervals resulting in reduced availability, frequent shutdowns, high maintenance cost and decreased engine performance due to fouling and corrosion. By combining both systems together, the major advantages of each can be attained. The first pulsing state of is designed for extremely dusty environments. The self-cleaning action during operation allows continuous operation at low stable pressure drop, eliminating the need for frequent replacement of static pre-filters. The cleaning system is activated as a function of the dust load and avoids sudden increases in pressure drop. The final stage of HEPA filter provides a barrier against the smallest and most corrosive particles which has been proven to significantly reduce or eliminate corrosion and fouling. As well, the water repellent design provides protection under even the highest humidity levels.

Inertial Seperators

AFi's inertial separators are extensively used In regions with great dust concentrations, intake air can efficiently be cleaned by our inertial separators. The eliminated dust is ejected to the outside by a secondary-air fan, minimizing operating costs by avoiding exchangeable filter media.

Pulse Filter System

AFi's self cleaning pulse filter systems are effectively used where high dust concentration prevail, such as desert areas & specially in polluted industrial regions. The dust particles are captured on the surface of filter medium. The dust cake that results is effectively removed on-line by a counter-flow pulse-jet cleaning process with compressed air. According to the local conditions, the pulse filter cartridges are configured horizontally (cross-flow systems) or vertically (table filter systems).

Pulse Jet Catridge Systems

A wide range of options to meet your needs and budget, AFi provides an extensive range of pulse jet cartridge filters to meet all of your micro filtration needs. The AFi Cartridge filter range covers filters for Pulsing and Static applications. Media options for cartridges are Water Repellent Micro glass Fiber, Resin Impregnated Cellulose, Cellulose and synthetic blend, or wet laid synthetic i.e. 100% moisture resistant. A rigid expanded metal is used as inner core and outer core that protects each element from extreme differential conditions and handling damage respectively. The inner and outer cores are bonded with the pleated media with spiral hot-melt adhesive for better result.

Silencers

AFi can provide various solutions to the problems presented by air induction noise through the use of various forms of annular or rectangular intake silencers. These can be made in an appropriate size to suit the characteristics of the flow system. The available designs vary from the simple annular ?clean straight-through? acoustically packed intake silencers, or designs with a central pod or annular splitters. These units can be placed between the engine and the corresponding filtration unit.

Static Filter Housing

AFi's Static Filter Housing is suitable for regions with relatively low dust concentration. Most frequently, a two/three stage filtration is selected in order to achieve the required filter class & service life. A droplet separator is additionally integrated for climates with long periods of high humidity or fog. In zones with extremely high degrees of outdoor wetness (e.g., in coastal areas), an additional upstream coalescer is recommended.

Static Filter Housing (with anti icing system)

AFi introduces a unique Anti Icing System for its static type filter housings which are installed in regions with low temperatures occurs with high humidity. During such weather periods, this system prevents the formation of ice, which could lead to rapid increase in pressure drop or even to blockage of air filters. The bandwidth of AFi's Anti Icing System includes heat ex-changers, warm- and hot air distributors, infrared systems & electric heaters.